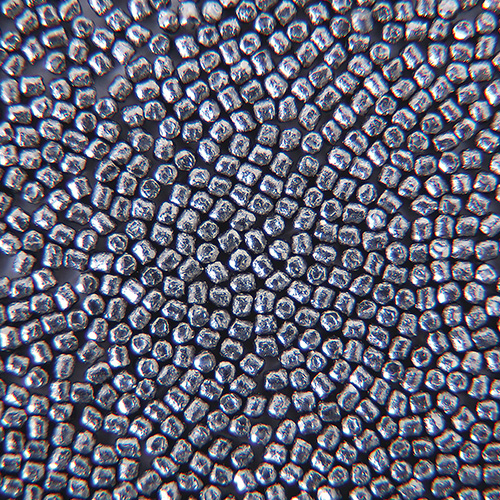

Conditioned steel cut wire

for shot peening

FROHN conditioned steel cut wire is used in shot peening applications for optimising the fatigue properties of safety critical components in the aviation, automotive, and their supplier industries.

Application fields

Surface hardening in the automotive and aviation industries

Applications

- Chassis/undercarriage/suspension components

- Engine and gear parts

- Motive units

- Chassis/undercarriage

- Airframe parts

Specifications

Design purpose:

Surface hardening (shot peening)

Material:

1.0517 (C48D)

1.0586 (C50D) – 1.0609 (C58D)

1.0617 (C72D) – 1.0614 (C76D)

1.0626 (C82D) – 1.0616 (C86D)

Other materials on request

Manufacturing standards / applicable specifications:

VDFI 8001, (DIN 8201-4), ISO 11124-1, AMS 2431-3, AMS 2431-8, AMS-S-13165, SAE J441, GE-Spec., BAC-Spec., etc.

Sizes:

0,3 mm 0,8 mm

0,35 mm 0,9 mm

0,4 mm 1,0 mm

0,5 mm 1,2 mm

0,6 mm 1,4 mm

0,7 mm 1,6 mm

Other sizes on request

Grain shape:

Cylindrical, G1 slightly rounded, G2 double rounded, G3 spherical conditioned

Hardness class for rounded shapes:

610 HV0,5/1 – 670 HV0,5/1

640 HV0,5/1 – 700 HV0,5/1

670 HV0,5/1 – 730 HV0,5/1

750 HV0,5/1 – 850 HV0,5/1

Packaging:

– 25 kg PE bag on EUR-pallet (max 1000 kg)

– big bags max 500/1000 kg on expendable pallet

– 200 litre barrels max 800/1000 kg

Other packaging on request